The traditional way to build deck sub-frames is as much to restrain movement in the materials as it is to do its job as a deck frame. This is due to the fact the timber absorbs so much moisture, it's very hard to stop it from moving and keep it straight and true when it dries out.

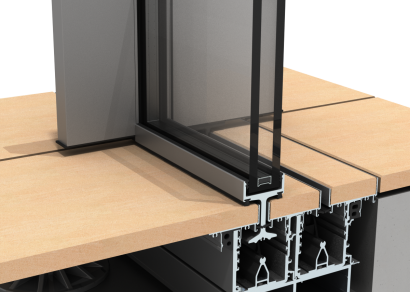

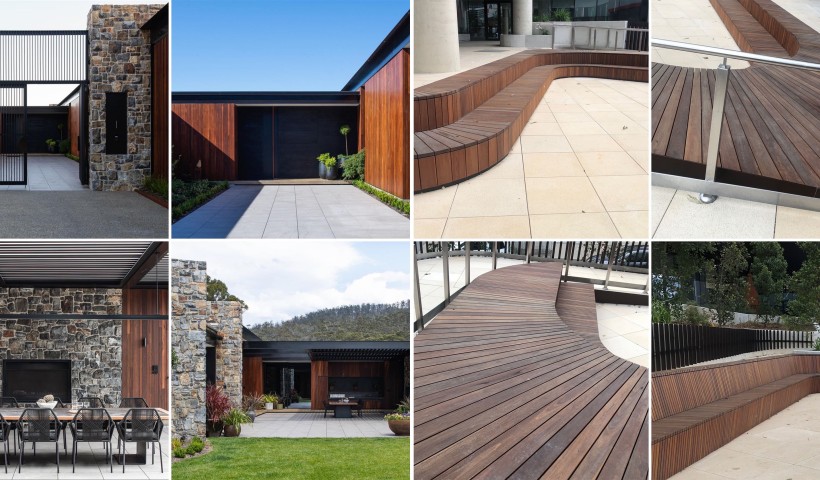

Outdure has made a significant breakthrough, replacing traditional materials with a small selection of multi-use, moisture-resistant components, creating a completely flexible, cost-competitive deck frame system called Qwickbuild. It's a simple concept: use better quality materials and slash the labour content.

Outdure has figured out a way of being able to make a deck frame with less materials, that are stronger, lighter, straight and far more easy to handle. Qwickbuild enables a level of precision and assembly speed completely unheard of in the building industry.

Supplied in either made-to-measure frames, kitset or loose components just like Meccano, Qwickbuild is typically assembled in a matter of hours, and can be assembled in the most complex of deck configurations.

To learn more about Qwickbuild visit the Outdure website, or use the free bearer/joist/decking board optimisation service.

Product News

Product News

Popular Products from Outdure

Popular Products from Outdure

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts