In the world of non-structural elements, there is a great tendency to think of partition walls and glazing lines as temporary, as design elements and as finishing touches. This couldn't be further from the truth.

With the damage from earthquakes around the country rendering structurally sound buildings economic write-offs, the focus on non-structural elements has sharpened.

Meeting council demands for design and compliance has become easier with recent innovations within the interiors market.

What the Building Code Says:

Turning to the building code for guidance on what is required for bracing best practice, Clause B1 Structure, B2 Durability, F2 Hazardous Materials and other cross-over codes can be found. These outline what is required to properly brace non-structural items. Clause B1 specifically states the need to safeguard people from injury, loss of amenity and protect other property from damage caused by structural behaviour or failure.

Then parts loading can be found in AS/NZS1170.5, giving the minimum requirements for a robust bracing system. The need to adhere to building code B1 Structure, utilising AS/NZS 1170.5 and AS/NZS 4219 comes from the intention of the code to protect life, preserve egress in emergencies and to ensure the continued operation of the businesses contained within the building.

Take into account wind loadings, snow loadings and earthquake parameters (SLS and ULS) and the parameters for a bracing system that performs are found.

Bracing Checklist

Those involved in the interior fit-out industry know how difficult it has been to comply with building code requirements and ceiling manufacturers' warranties. For decades the manufacturers of two-way ceiling grids have stated that no materials should be connected to their product, and for decades this requirement has been largely ignored.

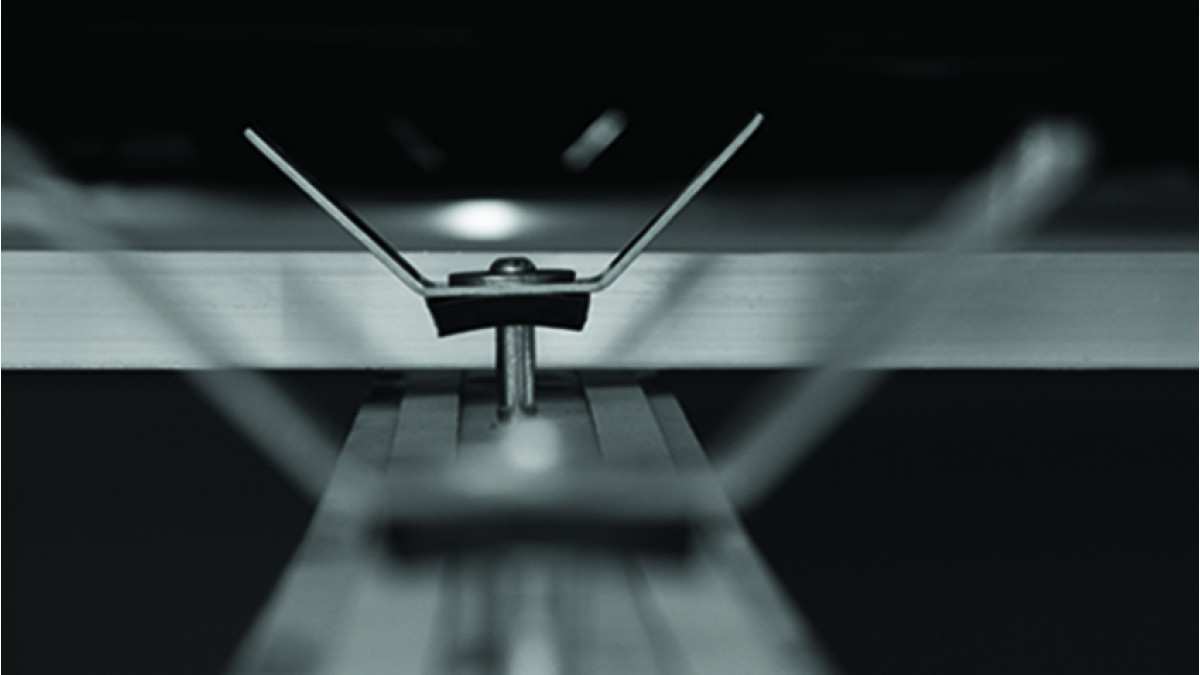

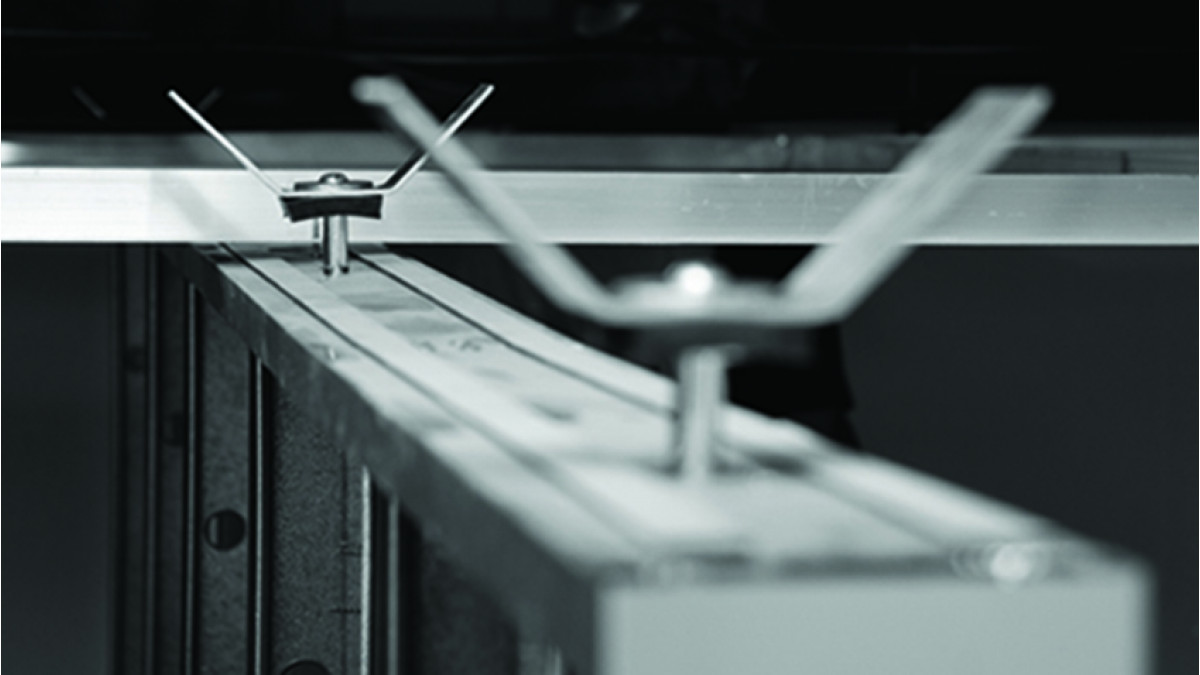

The Tracklok proprietary bracing system is easy to install, cost-effective and complies with building code requirements and ceiling manufacturers' warranties. Let's look at how all the parts of an interior fit-out project come into play and how they relate to bracing.

Ceiling Grid

Ceiling grid is designed to carry its own weight, measured at approximately 15kg/m² or less. Attachment of a partition wall or glazing line to a suspended ceiling will exceed this weight, and restrict the ceiling grid's design performance. Remember, partition walls weigh 40kg/m² or more, while the glass from glazing lines weighs in at approximately 25kg/m².

In addition to this, the ability of the ceiling grid to support itself during a seismic event is grossly compromised when walls are connected against the manufacturer's specification. Walls connected to the two-way grid will cause the two-way grid to fail, resulting in significant damage.

Partition walls and glazing lines need to be braced at all times, at a minimum of 40kg/m² as these walls have the weight to create catastrophic failure when horizontal deflection occurs.

Partition Walls

Bracing needs to allow for horizontal deflection of up to 40mm each way, while allowing for inter-story drift of 50mm. There is also a need for 90mm of in-plane deflection, which is required when the floating head of the partition wall moves in line with the wall.

Although vertical deflection is taken up in the construction of the wall itself, there are some projects where the connection to widely spaced C purlin top floor roof structures means additional vertical deflection may be required.

Service Clashes

The improvement in the coordination of service trades continues and as early collaboration improves, service clashes will be greatly reduced.

Bracing of walls, ceilings and services need to be considered early in the design and construction process to allow efficient sequencing on site.

Using a bracing system that provides for flexibility, in terms of bracing angle and direction or placement can allow partition installers to mitigate most service clashes.

Case Studies

Case Studies

Popular Products from Potter Interior Systems

Popular Products from Potter Interior Systems

Posts by Michael Freeman

Posts by Michael Freeman

Most Popular

Most Popular