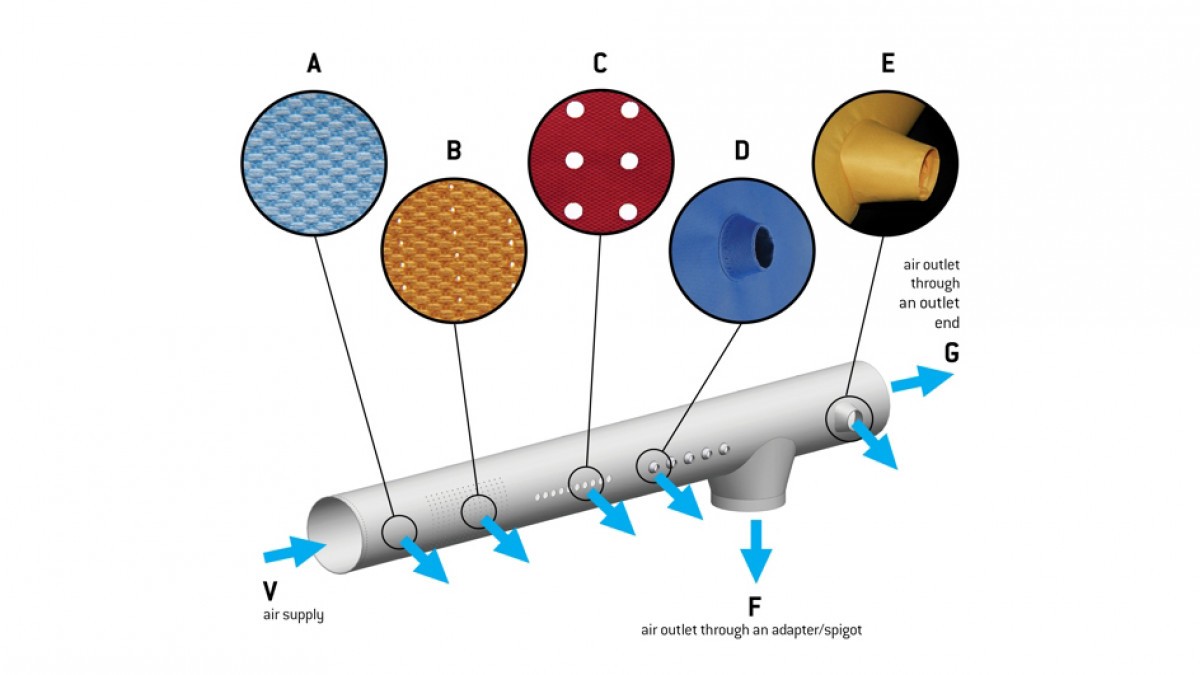

Prihoda is a Czech company who truly understand air temperature and air movement. They have developed textiles that are cleanroom quality, strong, flame-resistant, and have a 10-year warranty. Every air distribution system is designed from scratch specifically for each site and application. Recycled fabric options are also available and are manufactured from used plastic bottles, with reduced consumption of energy by 66%, water by nearly 50% and greenhouse gas emissions by over 34%. Fabric air ducting and diffusion can cater to a diverse range of industries such as indoor pools, schools, laboratories, food, sports, light structures, offices, restaurants, cinemas, retailers and many more.

Fabric ducting has considerable advantages over other types of HVAC ductwork. It provides more controlled air velocity and a comfortable environment with lower noise levels than rigid ducting. Greater safety is offered by the higher fire resistance of the material over plastic ducting. No seismic restraints, other than the cable system that supports the very light weight of the duct, are required to meet NZ standard (NZS4219:2009) for earthquake safety. Maintenance is also arguably much easier with fabric ducts as they can be removed (unzipped), machine washed and re-installed. Fabric ducting systems cost less than rigid ducting and the associated grilles, especially if that system has to be insulated. It also takes less time to install.

Perhaps the greatest feature of fabric ducting for those who are creatively minded is a customisable look that has the ability be fashioned using any colour or with printed graphics that make this product a uniquely artistic ventilation option.

Product News

Product News

Popular Products from Hot Water Heat Pumps

Popular Products from Hot Water Heat Pumps

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts