NEW

NEW

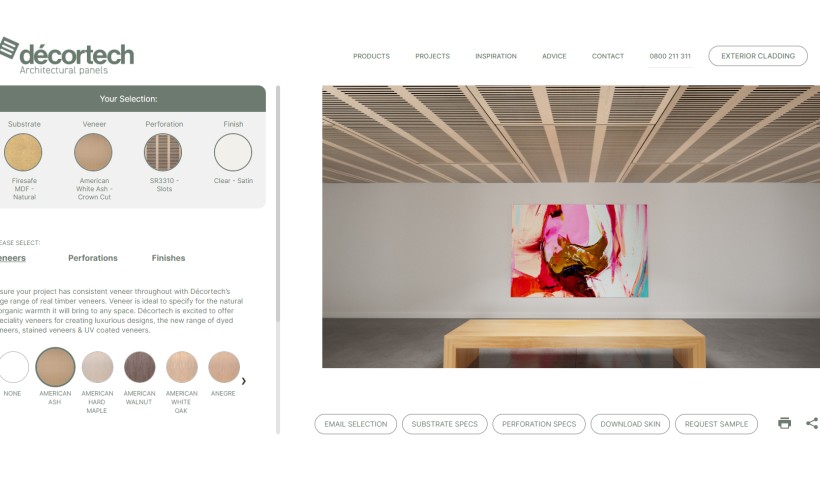

All Décortech panels are pre-finished, saving time and costs on site and reducing potential on-site issues such as spills or overspray. Panels arrive on site fully finished and once installed there is no further work required. Panels can meet Group 1-S fire rating requirements, meaning there is no need for messy intumescent coatings to be applied on site.

Décortech’s extensive knowledge and robust processes allow a close collaboration with architects and installers to work out any issues during the shop drawing process. Precision shop drawings are created, checked and amended if necessary to ensure panels are correct first time. Creating shop drawings gives the ability to identify any potential issues before manufacture, ensuring the highest quality product and reducing any potential risks on site.

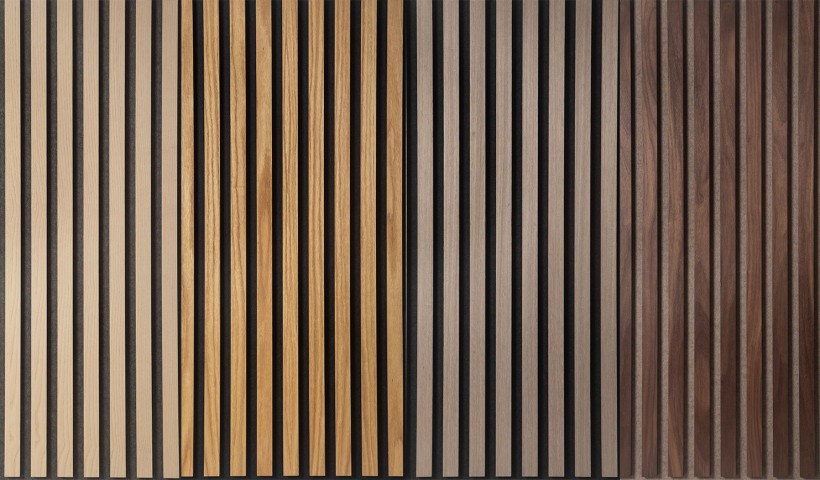

Décortech manufactures all panels in Penrose, Auckland. With top of the line CNC machines and Paintline, Décortech can respond with quick turnaround times when required to meet tight project timeframes and to deliver panels on time, without compromising on quality. The large range of substrates, real timber veneer and paint options, including the new matt finishes, ensures the panels can be customised to suit any design.

Décortech panels were specified on the new AUT M1 building. Two panel types with three different finishes were specified, including a customised Dark Stain. With the intricate curved design in the Crush Space, Décortech worked with the installer with templates of the design. These templates meant once Décortech manufactured the panels they were able to be delivered to site on time, and the panels were installed without hassle or worry of them not fitting.

Décortech Pre-finished panels are ideal for any project and eliminate the need for on-site construction, extra scaffolding and further painting, enabling savings on time and installation costs.

Décortech panels will enhance any project, introducing warmth and elegance.

New Products

New Products

Popular Products from Big River Panels

Popular Products from Big River Panels

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts