NEW

NEW

New Resene FX Nightlight is a waterborne glow-in-the-dark paint designed to shine after the lights have gone out. It's ideal for safety signs, children's areas (paint planets and stars on walls and ceilings, or around the light switch so they can easily find it in the dark), step edges or anywhere a glow in the dark effect may be required. The paint glows in the dark by night, and is pale yellow by day.

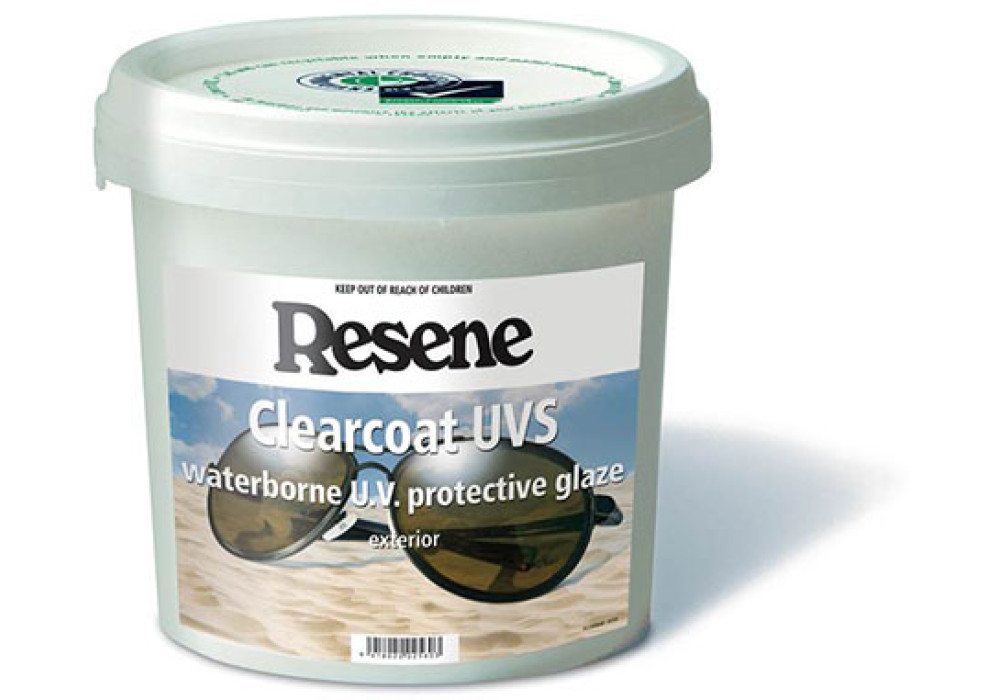

Simply paint two or three coats of Resene FX Nightlight over a white basecoat, such as Resene Lumbersider, for the best effect. For exterior use, finish with Resene Clearcoat UVS for extra durability.

The paint glows brightest when the lights are first turned out and then gradually wanes after being in the dark for about two hours. The more paint applied, the stronger the effect. Resene FX Nightlight is available from Resene ColorShops and selected resellers.

How does glow in the dark technology work?

Normal light is always associated with heat and the fact that, as a substance is heated, its individual atoms get very agitated and release most of the newly acquired energy as light. The hotter the material gets, the brighter the light that is emitted until the material becomes 'White Hot'. Luminescence on the other hand, produces light without significant heat input.

On being bombarded with photons, the outermost electrons surrounding the atoms in a photo luminescent crystal or pigment become very agitated and get raised to an excited state. They leave their friendly orbit, leaving an 'electron hole' behind, and roam as a singlet exciton. In this quantum world, the singlet state is not very satisfying and the excitons can decay, emitting a photon, after a life span of about 108 seconds. This may seem to be a very ephemeral life but it does give the phenomenon of 'fluorescent' pigments.

The singlet excited electrons enter into a triplet and they enter what is described in quantum physics as a 'forbidden energy state'. In this state these triplets wander around the pigment crystal, often getting ensnared in electron 'traps', for a quantum eternity until they find a free quantum hole to collapse into, giving up their destabilising photons.

The first recorded investigations of synthetic photoluminescents were done, in 1603, by Vincenzo Bascardiolo, who heated a mixture of barite and coal. The powder obtained after cooling exhibited a bluish glow at night, which could be restored by exposure to sunlight. What had formed was a barium crude sulphide.

A major advance was made in the 70s with the discovery that certain alkali aluminates provided a very useful base material for photo luminescent pigments. Europium and dysprosium now provided the dual function of not only encouraging the roving electrons to leave their nest, but also providing new nests which encouraged them to give up their photons when the time was ripe. They also became skilled in introducing 'lotus land' flaws in the crystal where triplets of electrons could carelessly while away many pleasant seconds, delaying the emission time of the photon.

The manufacture of these materials is by a melt process and the technology is so precise that the dopants need to be precisely spaced within the base crystal, via the use of fluxes. Particle size is critical as is the need to manufacture precisely without using white or tinters. Contamination from even stainless steel vessels can 'poison' the luminescence.

See Resene Architects memo 123 for more information on photoluminescence.

Case Studies

Case Studies

Popular Products from Resene

Popular Products from Resene

Posts by Resene Technical

Posts by Resene Technical

Most Popular

Most Popular