There’s more than one way to hug a tree. Ferran de Miguel Mercader, Sustainability Business Partner at Laminex New Zealand, believes in showing the love by making full use of all its assets.

“It takes a lot to grow a pine tree — on average 28 years, so you want to make good products from it,” says Ferran. But that’s not all. In the business of providing decorative surfaces to customers, Ferran is building a strategy to ensure the company operates in a sustainable manner — one that is respectful of the environment, conserves energy and minimises waste. “It’s a journey,” he admits. “But we have a roadmap that focusses on continuous improvement.”

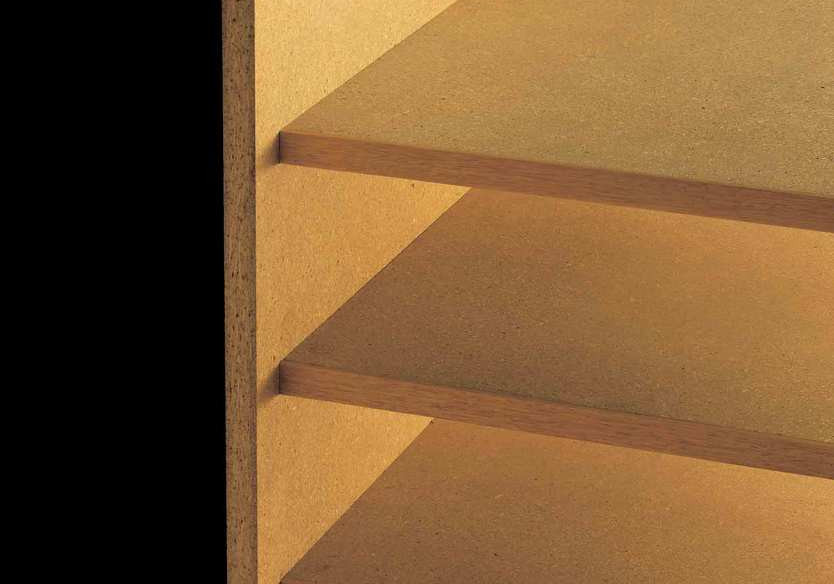

The aim — for a 30% reduction in carbon emissions by 2030 — means making greener decisions in the here and now. One place this ‘getting better everyday’ approach can be seen in action is at the Laminex New Zealand manufacturing plant in Taupo. This is where the company makes the particle board that is the substrate for their high-pressure laminates (HPL).

Roughly 70% of an average Pinus radiata is milled into timber. The rest — those scrappy bits at the top of the tree — goes into fibre-based products including particle board. In Taupo, the machinery used in the factory is driven by 93% renewable energy. “More than 75% of this energy is derived from biomass,” says Ferran.

Laminex New Zealand sources this biomass in the form of bark and wood from the neighbouring sawmill in Taupo, thus chewing up their ‘waste’ from the very same trees that provide the raw materials for their products.

Once the particle boards are formed at Taupo, the surfaces are smoothed ready for the application of the HPL. This creates a significant volume of sander dust. While dust usually signifies the end of the road, that’s not the case here. Laminex New Zealand has invested in a system to transform the powder-fine particles of sander dust into briquettes, a renewable energy source that keeps 72 wheelie bins of dust out of landfill each day.

Moving towards a circular economy where products are reimagined, recycled and repurposed at the end of their life is a huge and sometimes daunting goal but a worthy one.

Which brings us back to that tree: Laminex New Zealand is the connector which links the pines to wood-based products which, in turn, echo the natural world. Along the way, they’re cutting emissions, sending less waste to landfill and continue to investigate end-of-life solutions. As Ferran puts it, “When it comes to the circular economy, we are committed to closing up the loops.”

Case Studies

Case Studies

Popular Products from Laminex New Zealand

Popular Products from Laminex New Zealand

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts