In an era where environmental sustainability is no longer optional but imperative, the construction industry seeks innovative materials and methods that align with green building principles. Vulcan's invigoration of UltraClad and UltraBatten aluminium systems after acquiring Ullrich Aluminium marks a significant stride towards this goal, showcasing the pivotal role of sustainable practices in modern construction projects.

With an emphasis on sustainable material sourcing, Vulcan now sources its aluminium for Building Systems locally from Tiwai Point, one of the lowest global embedded carbon aluminium sources. This strategic choice not only supports the local economy but also significantly reduces transport emissions, highlighting Vulcan's holistic approach to sustainability. The company's commitment extends beyond sourcing, embracing the principles of a circular economy through an effective recycling program. By ensuring that all production waste is redirected to local re-melt facilities, Vulcan turns potential waste into reusable infeed billet, emphasising aluminium's role in future sustainable building practices.

The finishing process for these systems is powder coating, a method with key environmental benefits. This process not only allows for the recycling of overspray but also eliminates the traditional need for repainting and reduces VOCs, further minimising the ecological footprint of Vulcan's products. Vulcan are also transitioning all powder coating to chromate-free powder coating facilities

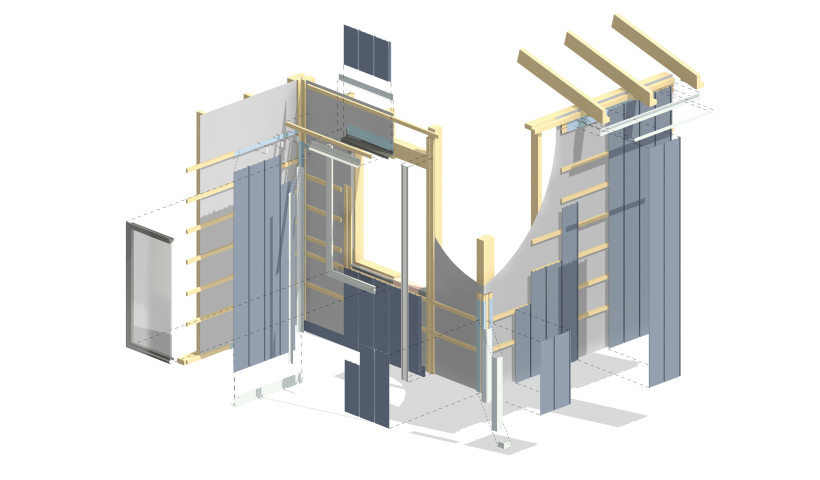

During the specification process, Vulcan’s in-house extrusion and production planning allows for precise material planning and increased material yield for the total project, saving both money and materials.

Vulcan's broader environmental initiatives, include investments in solar energy and the exploration of electric and hybrid transport solutions, underline the company's comprehensive commitment to reducing the impact on the planet.

Case Studies

Case Studies

Popular Products from Vulcan Building Systems

Popular Products from Vulcan Building Systems

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts