What if:

- a decking subframe could be pre manufactured in a factory and delivered to site just like aluminium joinery?

- that subframe was light enough for two people to lift off a truck and position into place?

- the number of structural supports could be reduced by 30%?

- decking boards could to be installed using no screws or nails?

- 25m2 of decking boards, including picture framed edges, could be assembled in less than one hour?

QWICKBUILD, the worlds first prefabricated deck subframe system, addresses all of these issues.

For the same cost as an installed traditional pine substructure, you can now substitute expensive decking installation labour costs for superior quality materials that will never rot, warp or leech chemicals.

Enjoy speedy project completion and the assurance your deck will stay straighter for longer.

QWICKBUILD can be used as a direct substitute for traditional deck timber joist and bearer subframe installation. Designed to be used in conjunction with any of OUTDURE's composite ECO-DECKING range, you have timber decking alternatives to specify over waterproof membranes or ordinary decking applications over soil or concrete.

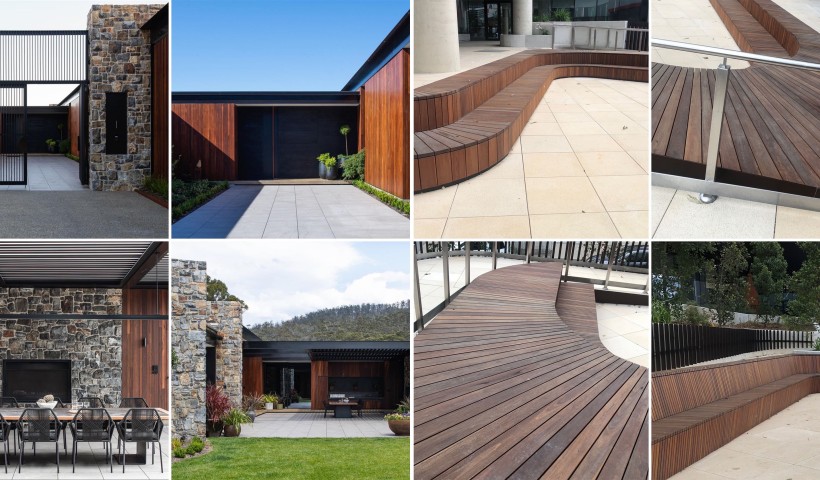

Case Studies

Case Studies

Popular Products from Outdure

Popular Products from Outdure

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts