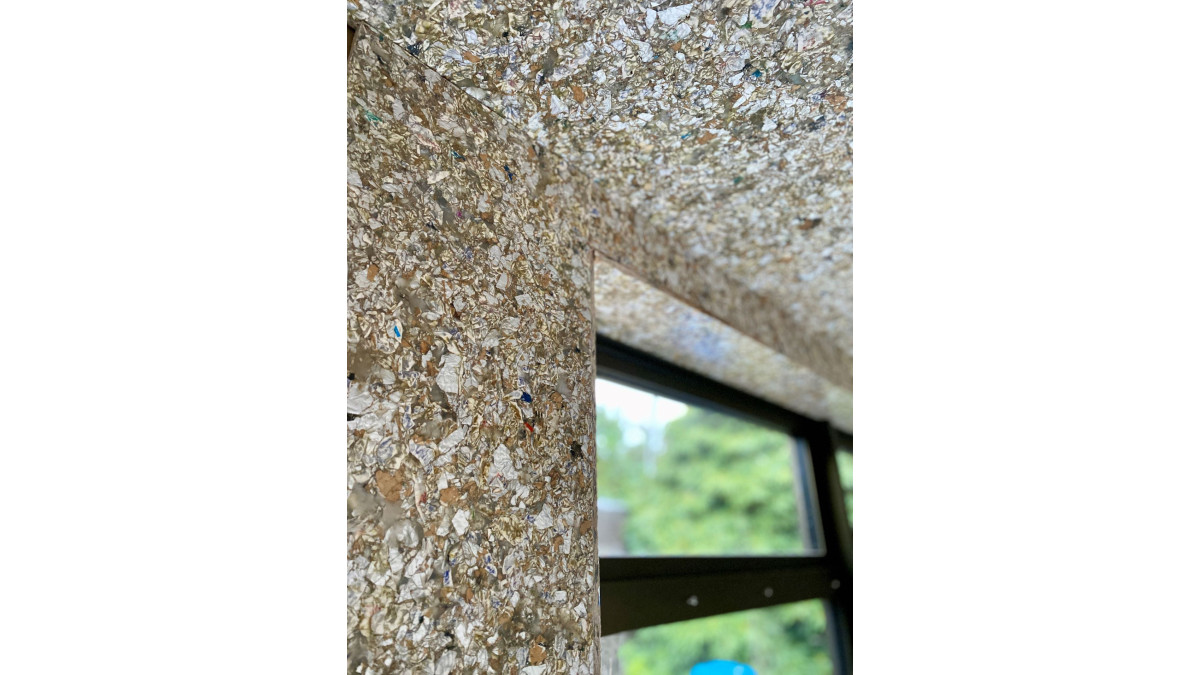

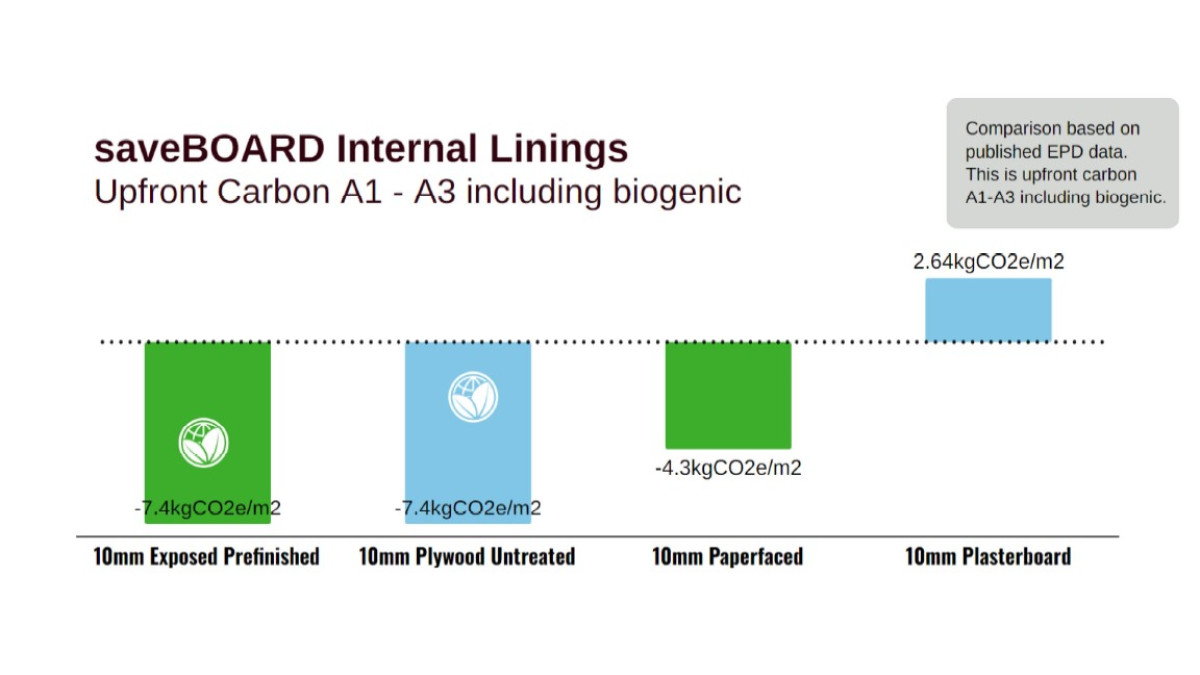

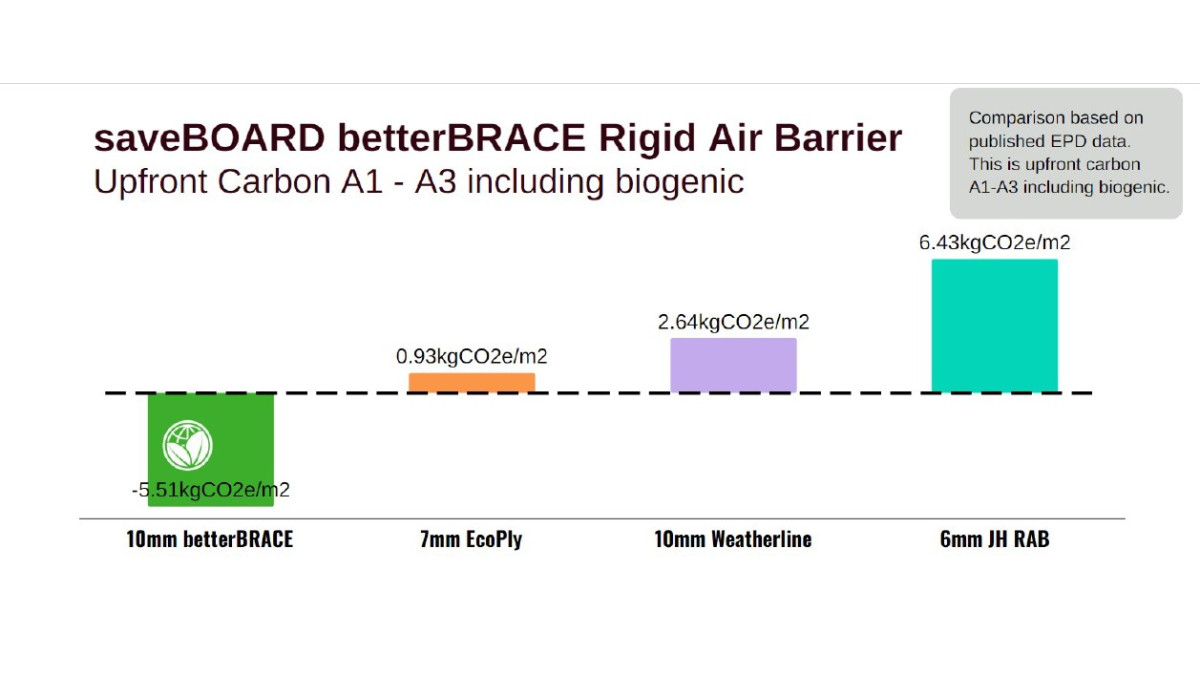

saveBOARD is transforming the building materials industry by manufacturing products from 99% recycled composite packaging, soft plastic, and recycled board. Their innovative approach not only diverts an average of 25 kilograms of waste per board from landfills but also achieves a groundbreaking negative Global Warming Potential (GWP). The Cradle to Gate (A1-3) impact of saveBOARD products ranges from -10.0 kg CO2/m² to -4.35 kg CO2/m², including biogenic carbon.

Understanding the negative impact

Paula Wallace, National Specification Manager at saveBOARD, explains that the negative GWP results from the unique lifecycle of their products. The Cradle to Gate phase, where most greenhouse gas emissions occur, is significantly improved through their use of recycled materials. Traditional manufacturing processes involve emissions from raw material extraction and land use, both of which contribute to greenhouse gases. However, saveBOARD’s products avoid these emissions by using recycled waste materials, which do not require raw material extraction or land disturbance.

Additionally, saveBOARD’s products benefit from biogenic carbon. Wood products, including those made from paper, contain carbon dioxide (CO2) absorbed during the tree’s growth, which remains sequestered in the final product. This biogenic carbon contributes to the negative GWP, as the carbon remains stored in the recycled paper that constitutes about 70% of each board. Through saveBOARD’s Product Stewardship Program, off-cuts and end-of-life products are also recycled, promoting a circular economy.

Case study: Elevate Homes, Cambridge

A practical example of saveBOARD’s impact is its adoption by Elevate Homes, a company specialising in architecturally designed transportable homes. Elevate Homes recently switched from a 7mm plywood rigid air barrier to saveBOARD’s betterBRACE rigid air barrier. For a 150m² home, this change resulted in a carbon saving of 268 kilograms and every home diverts 1,000 kilograms of waste from landfills. Elevate Homes has integrated a circular approach by recycling all on-site soft plastic waste into betterBRACE and utilising saveBOARD’s cut-to-length service to minimise product waste. Any off-cuts are also recycled into new boards through saveBOARD’s Product Stewardship Program.

Lee Turner, Director at Elevate Homes, emphasises the dual benefits of this choice. "We use saveBOARD betterBRACE as additional bracing in all of our homes. SaveBOARD's use of 99% recycled materials makes it revolutionary. It transforms soft plastics and other everyday packaging waste into sustainable, high-performing, low-carbon building products. Each sheet of saveBOARD we use positively impacts both our homes and the environment. It’s a win-win situation."

Certification and future

saveBOARD’s commitment to sustainability is further validated by its EcoChoice Certification and DECLARE label. Their Environmental Product Declaration is in the final stages of verification, reflecting their dedication to transparency and environmental responsibility.

saveBOARD stands at the forefront of sustainable construction materials by integrating recycled content and promoting a circular economy, all while significantly reducing carbon emissions. Their partnership with companies like Elevate Homes showcases the practical benefits and positive environmental impacts of choosing truly sustainable building solutions.

Case Studies

Case Studies

Popular Products from saveBOARD

Popular Products from saveBOARD

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts