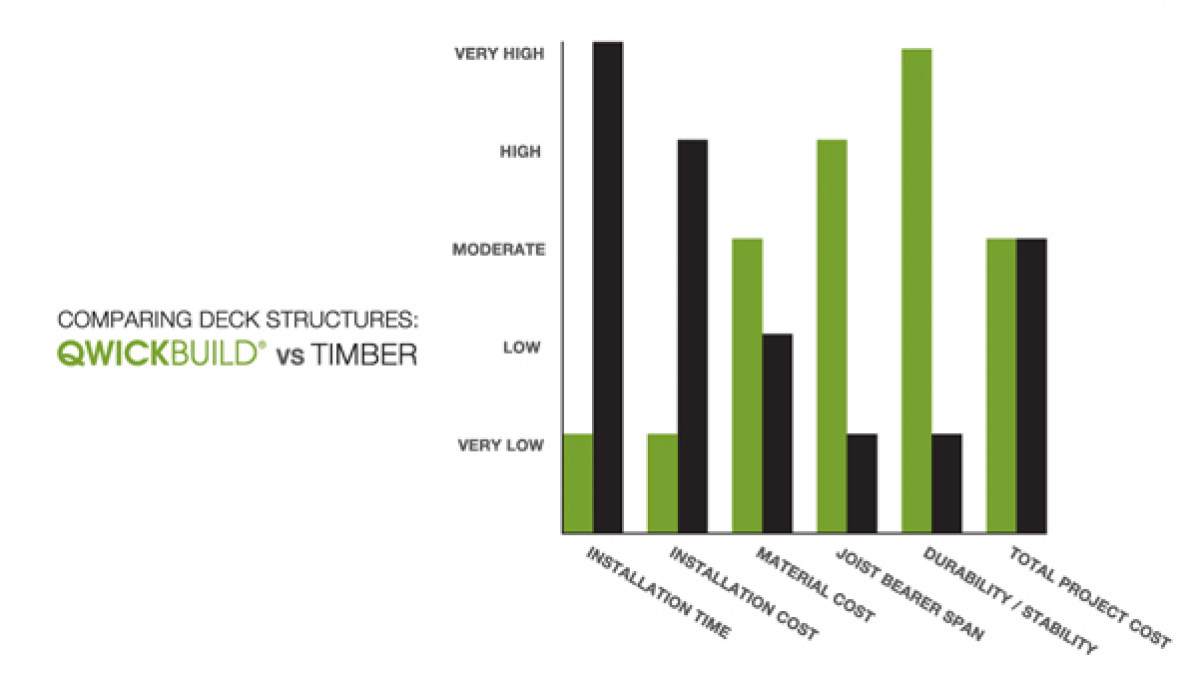

Until recently there hasn't been many options when it comes to choosing materials for deck frame construction. Traditionally it has involved constructing heavy, cumbersome structures with often warped, chemically soaked timber joists and bearers. The installation has been time consuming and dependant on good weather, rather than to meet a budget. Outdure has changed all of this with its made-to-measure Qwickbuild deck frame system.

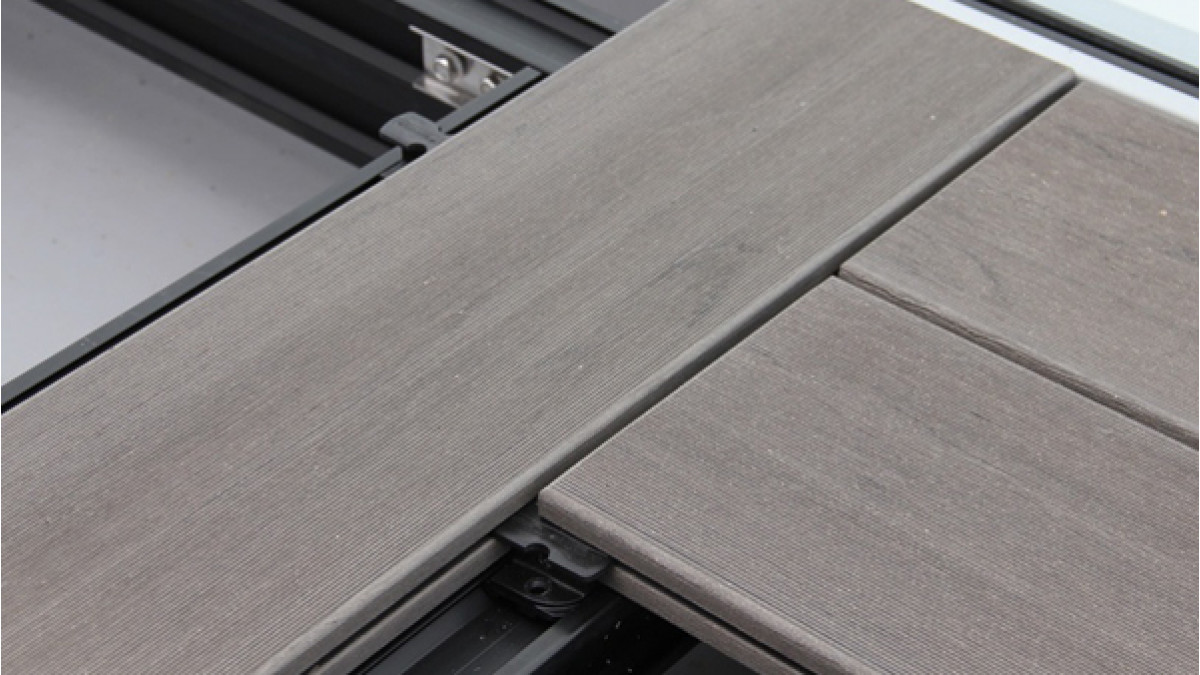

Made from marine grade anodised structural aluminium and 304 stainless steel components, Outdure's Qwickbuild deck framing system has numerous benefits. It is moisture proof and therefore very dimensionally stable. It is lightweight, high strength with long spans and is incredibly durable.

Made-to-measure deck frames are designed to your requirements free of charge, cut and pre-assembled then delivered to site or supplied as a kitset, making installation very fast and easy. No cutting, welding, fabrication or even pre-drilling is necessary on site. These massive installation savings make the cost of an installed Qwickbuild deck frame equivalent to the installed cost of traditional timber sub-frame, often cheaper.

Qwickbuild can be used in all decking scenarios: floating decks over a waterproof membrane, decking over existing concrete or pavers, low-height decks and raised deck structures. Qwickbuild is a comprehensive system that has virtually unlimited configurations.

Outdure's Eco-Decking, traditional decking hardwoods, structural tiles or turf and be installed onto Qwickbuild, although massive installation savings can be expected when using the screw-free Qwickclip concealed fasteners with Eco-Decking, a world-first patented innovation.

Case Studies

Case Studies

Popular Products from Outdure

Popular Products from Outdure

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts