At the recent NZIQS conference we were approached to discuss the merits of making provision in pre-cast concrete wall slabs, for a single point of entry passive fire penetration.

We discovered that where no provisions for passive fire penetrations had been made, concrete cutters were employed to core drill multiple holes in the erected structure. In addition to the direct cost of this activity, it was established that these holes were often drilled the wrong size for the specific service penetrating the wall. As a consequence, the cost of labour to re-work the penetration so that a compliant passive fire penetration seal can be fitted was in some instances more than the cost of drilling in the first place.

Coordination of Activity Saves Time and Money

It should be borne in mind that when the building element to be penetrated by a service is prepared in the prescribed manner, so as to facilitate the installation of a compliant penetration seal, no re-works should be necessary.

There are penetration seals tested to AS1530.4 and compliant with the NZBC that when installed in accordance with the manufacturer's specifications are cost effective on a supply and install basis.

However, the passive fire installation contractor/specialist is often not consulted in this process and as a consequence the preparation of the building element (and the timing of this activity) leads to un-budgeted costs.

Feasibility Comparisons

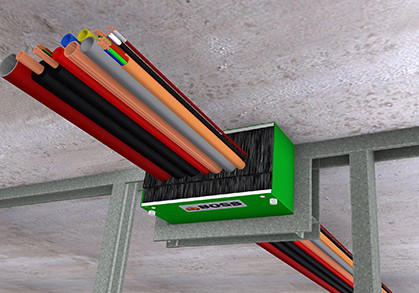

We conducted an elementary feasibility exercise using a Boss FyreBox multiple service, single point of entry, passive fire penetration and discovered that the direct cost of supply and install, including the cost of concrete drilling in the erected structure, was substantially lower than the traditional methods of supply and installation of separate service penetrations. When the indirect cost of possible re-works (as a percentage of the scope of work) was factored in, the true potential cost benefit became apparent.

We modified the exercise to reflect the position where the pre-cast slab included provision for the installation of the FyreBox in new builds and the picture became even more apparent.

Economies of Scale

When we extrapolated this saving over the number of apartments (fire cells) in the development in question, we found the figure was in the hundreds of thousands of dollars on the bottom line of the project.

Saving labour cost (time of installation), reducing the human error factor (cost of re-works), decreasing the cost of passive fire construction monitoring and having a compliant penetration seal specified into the QA process all contribute to delivering the project on time and within budget.

Economies of scale make it a 'no-brainer'.

Most Popular

Most Popular Popular Products

Popular Products