Curved walls are architectural features that add elegance and dynamism to interior spaces. However, the curvature complicates the traditional approach to panel installation. Mounting panels on curved walls poses a unique set of challenges, requiring precision and specialised solutions.

Here are a few issues you may come across and how Fastmount, a specialist in removable panel fixings, solves them:

Misalignment of panels during installation

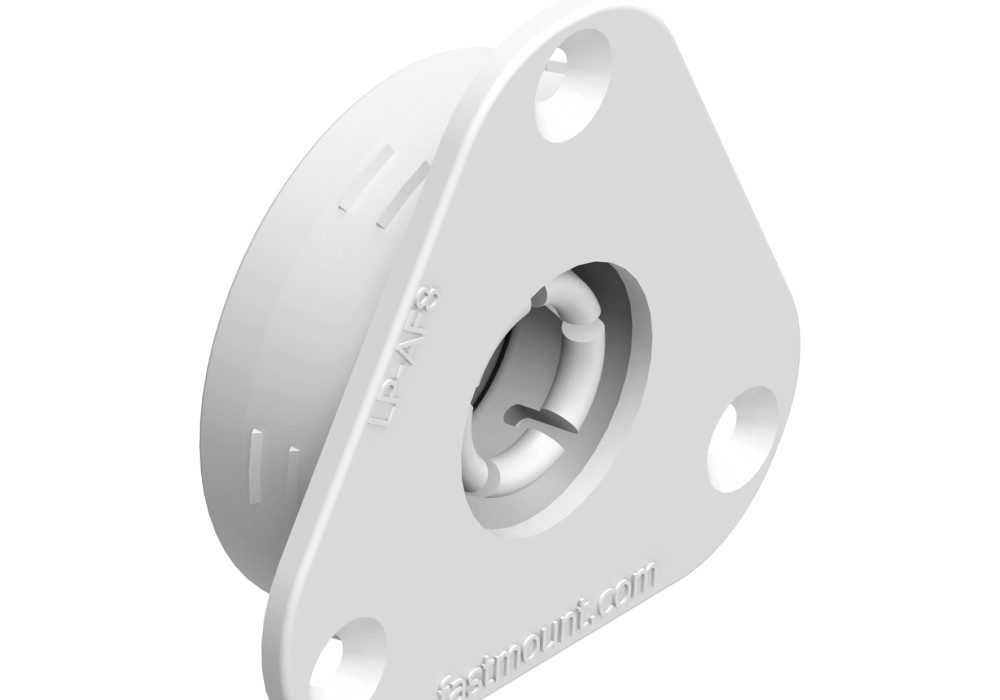

Fastmount was built for the challenges of curved walls with specially designed clips for this purpose. Fastmount provides a unique centre point for each product range that ensures perfect alignment. After installing the female clip into the substrate, clip in the centre point then offer up the decorative panel. This allows you to line up and mark your panels before commencing drilling and mounting. The five centre points available accommodate for different materials and subtrate, ensuring you can accurately pinpoint the holes where the clips need to go.

Some of Fastmount's clips allow for a few millimetres of adjustability giving that extra confidence that you can get the panel alignment perfect.

Complexity of the design and integrating it with other elements

Creating curved wall panels can be a laborious process and requires much more precision than flat panels. Not only do you have to manage the exact shape of the panels, but you also need to ensure that the wall surface you are mounting the panels on is consistent. If your design has shadow gaps on diagonal lines this magnifies the complexity. You may be panelling a curved staircase, so it needs to follow the shape of the steps. All these issues compounded means a standard solution like z-clips or French cleats will be very difficult to use.

Fastmount provide CAD (computer aided design) files for all of their products to make it easier to lay out the design. You can also use CNC cutting to pre-fabricate the panels off-site using your preferred digital modelling tool, so that the specifications are exact.

Higher costs due to longer installation times

Thanks to the availability of CAD files and the efficiency of the Fastmount panel mounting system, you can cut down on hours of labour to make the installation more seamless. Fastmount clips are also very cost effective both from the initial output but also due to their removable nature, allowing for much simpler maintenance and cleaning.

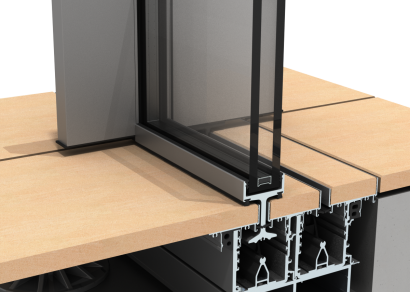

Achieving a flush and secure fit is crucial for curved wall panels, so necessitating a system that can adapt to the curvature while maintaining structural integrity is important. Fastmount provides a range of clips designed to simplify the installation of panels onto curved surfaces.

Depending on your project requirements, we would suggest choosing products from the Low Profile Range. The Low Profile Range offers self-tapping, screw and adhesive fix clips for mounting wall panels that require less space between panel and substrate. Available in 5-15kg pull out loads depending on the male clip used. The Low Profile Range is ideal for mounting wall panels, with female clips specifically designed to self-tap into curved substrates, drywall and MDF or foam core.

Make sure to refer to the specific install guides for your chosen products before beginning the installation.

By choosing the appropriate products for your project and following the steps outlined in the install guide, you can achieve a flawless and durable panel installation on curved walls, elevating the aesthetic appeal of any space.

Check out the case study on Spirit 111 by Spirit Yachts for a great example of how Fastmount clips can help you achieve the perfect finish for curved wall panels.

Visit Fastmount's product selector page to find the right clip for your project

Product News

Product News

Popular Products from Fastmount

Popular Products from Fastmount

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts