With a range of flashing products available (PVC, Metal etc.), why would DYNEXbuild consider entering into this crowded market?

The reason is that it has developed an innovative new product that will be very disruptive in this space.

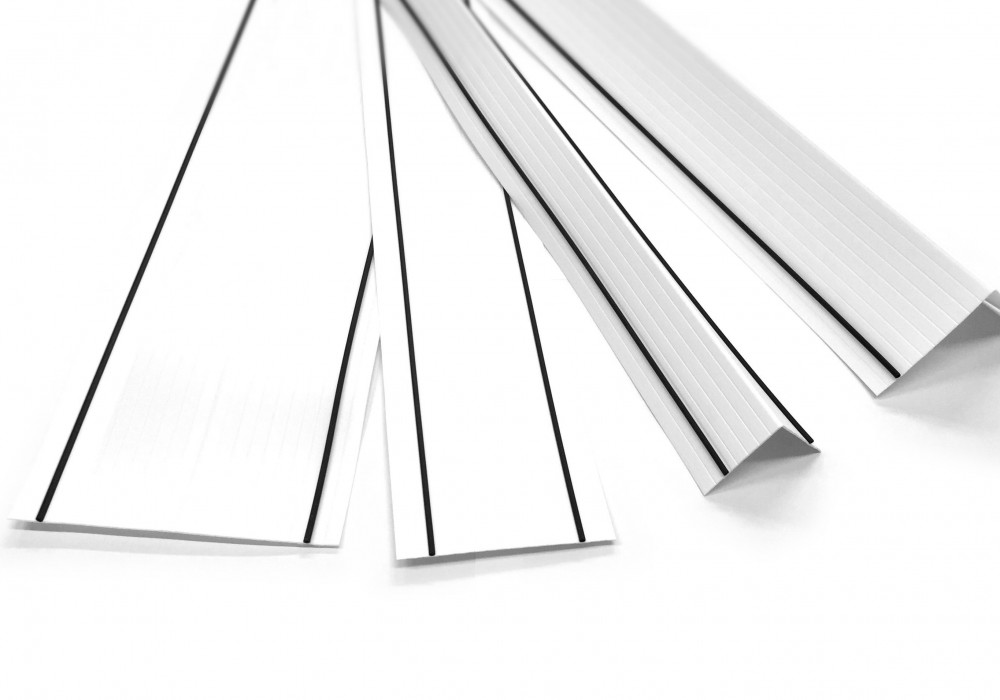

The concept was simple; make a cost-effective, functional and easy to use product. The new DYNAflash has it all. Because the builder cuts DYNAflash to the exact length required, waste can be eliminated. The high grade polymers used in manufacture have been independently tested for NZ conditions. DYNAflash is supplied in a clever dispensing box, making it convenient for the builder to handle and install.

DYNAflash comes in two sizes, 50 x 50mm or 75 x 75mm, both in a 25m coil.

The flexible hinge enables the product to be used for external corners, internal corners and flat junctions.

The DYNEXbuild team has cleverly incorporated the fixing strip into the flashing itself, reducing the need for fixings to penetrate the critical area between the beads.

The compressible co-ex bead is designed to help divert any moisture to the bottom of the flashing. Due to its compressible and slim nature, this bead will not push out the cladding, reducing unsightly cladding bulges.

On a recent build, Tony Hodge from Cladding Specialists said, "What an awesome product, so adaptable. I love the fact it comes in a box, so no need to join lengths and no waste. We clad more than 200 houses per annum and after using DYNAflash, we won't go back to the old stuff." Tony then discussed the specific job he was on at the time, "On this home we used DYNAflash 50 x 50mm as a back flashing on eight cladding junctions and saved nearly $100 over the cost of the product we normally use, and that is just on materials."

When looking to specify the appropriate flashing on your next design, look no further. The product has been BRANZ appraised and is proudly made in New Zealand.

Case Studies

Case Studies

Popular Products from Dynex

Popular Products from Dynex

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts