Step 1: Understand the movement requirements

The most important part of selecting the correct joint cover is to understand the movement requirements. Movement can be shown in the following ways:

- overall movement

- a percentage of the expansion joint width

- as a +/- movement.

A 50mm nominal expansion joint with an anticipated expansion and contraction of 25mm could be shown in the following way:

- 50mm +/- 25mm

- 50mm with a total movement of 50mm

- 50mm +/- 50%

The team at Construction Specialties recommends that when the engineer tells you the joint width, ask for the minimum and maximum dimensions at full movement. The engineer will indicate the location and width of the joints needed for movement to occur.

Step 2: Size the joints properly

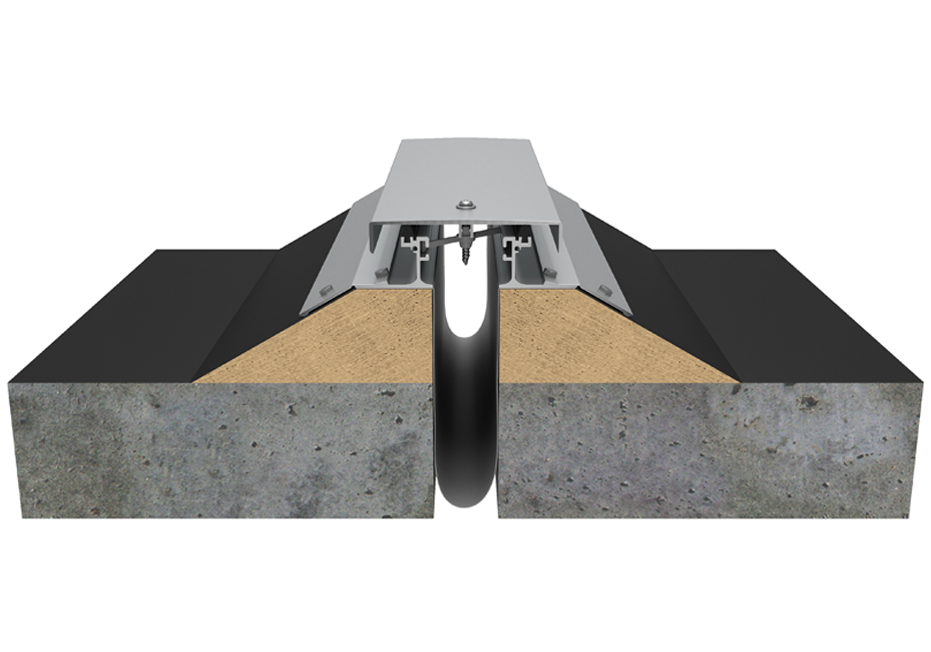

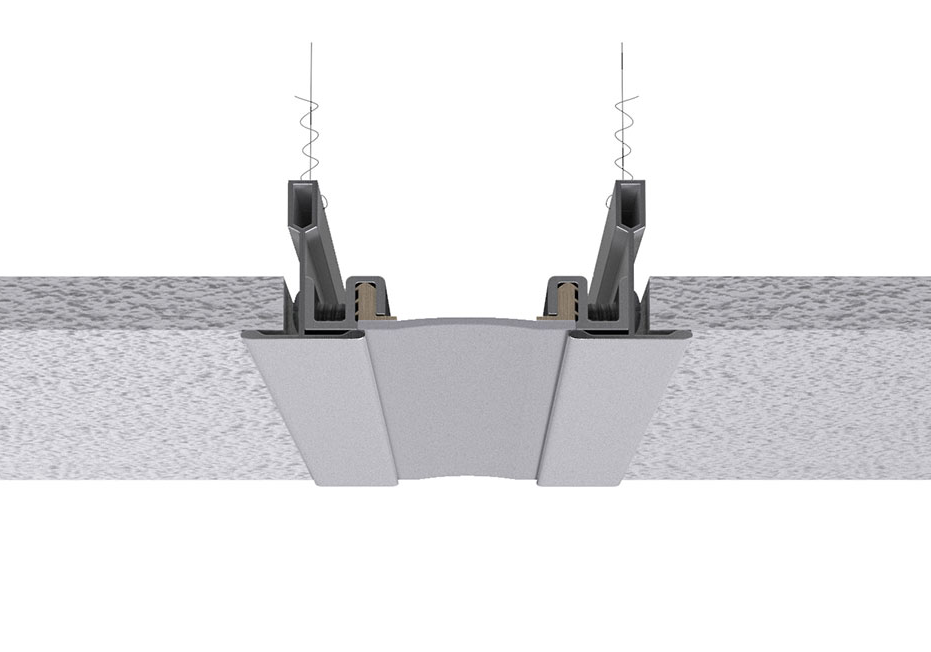

Most joint covers have components that take up space within the joint opening. It is important to remember that these materials will not allow a joint to close to 0mm without damaging the system or surrounding construction.

Exterior joints that run up the side of a building should be the same size from the roof to the ground. Any joint size changes on the exterior result in unsightly transitions and difficulties in maintaining weather protection.

Step 3: Joint locations and application requirements

It is important to consider the location of the joint before a selection is made. Generally, the floor cover application is the element most affected by the intended usage. Construction Specialties recommend starting with the floor cover and progressing from there.

When hygiene is an important consideration like hospitals, flush gasketed covers are often installed for ease of cleaning. For high traffic areas, the best choice is a hard-wearing metal cover.

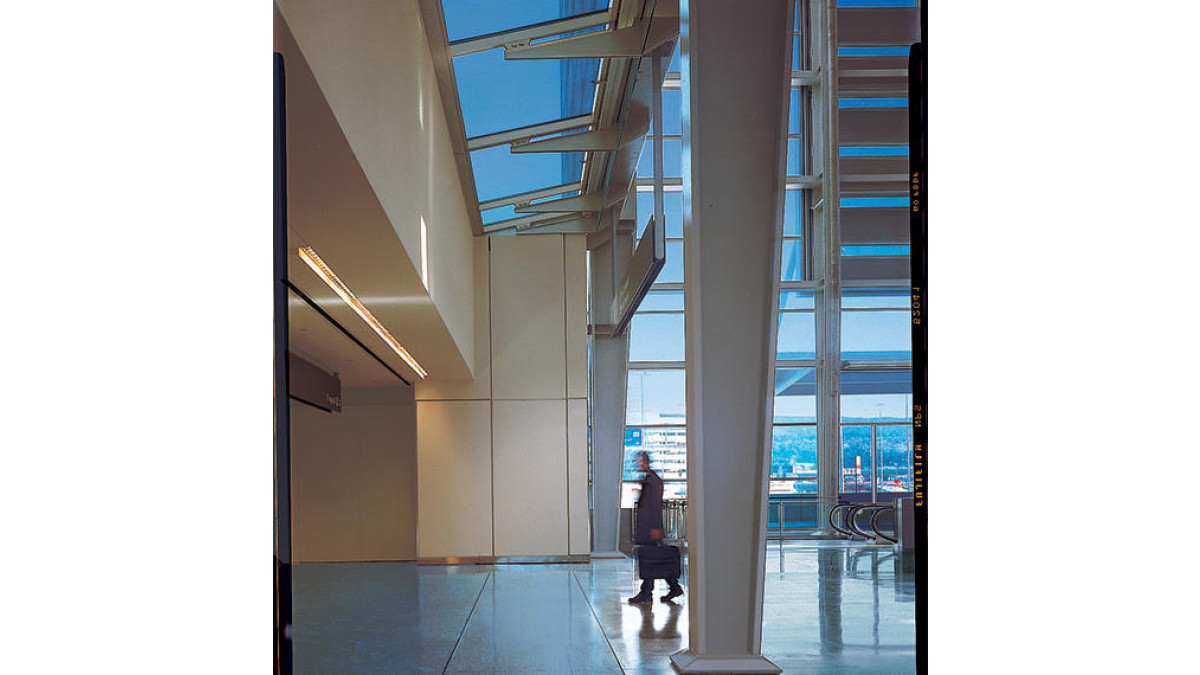

Heavy duty options are available for areas with very high traffic such as airports. For car parks, heavy duty rubber options are often used. When moisture ingress is an issue, waterproof joints are available, or moisture barriers can be incorporated into standard covers. In most cases fire barriers can be incorporated with an expansion joint cover to maintain fire integrity.

Step 4: Identify adjacent surface finishes

If the joint is located in a visible area where aesthetics are more important, consideration should be given to the adjacent floor and wall finishes. Most finishes can be integrated into the cover assembly to harmonise with the surrounding design elements, minimising the visual impact of the joint covers. There are a wide variety of joint cover systems available to meet form and function requirements, incorporating anything from vinyl floors to solid stone floor tiles.

Step 5: Joint type

The type of joint selected depends on aesthetic considerations and the required movement the joint must accommodate.

There are two types of joints to choose from:

- Surface mounted joints

- Recessed joints

Surface mounted joints are typically smaller with a single gasket or made from foam. Surface mounted joints are best suited for retrofit situations.

Recessed joints are typically larger mechanical joints or foam joints. Recessed mechanical joints will require a block-out to be formed prior to installation. Foam joints can be expensive and are not as robust as mechanical joints.

CSNZ have been manufacturing and installing seismic and expansion joints in New Zealand for more than 30 years. They offer a comprehensive range of joints and their expert team is available to support architects and designers throughout the entire process from concept to completion.

Case Studies

Case Studies

Popular Products from Construction Specialties

Popular Products from Construction Specialties

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts