NEW

NEW

Many authorities in the roofing market advocate “positive slope to drain”, usually between 0.5 and 2.0 degrees. Whilst Allco agrees with this view, they also recommend that practical roof decks should be constructed to provide an adequate slope to drain, particularly with conventional roof design. However, they do not subscribe to the concept that a roof membrane assembly must be sloped in every case, especially with Protected Membrane Roofs (PMR).

For clarification, a conventional roof assembly would typically consist of a structural deck in which an insulation layer is placed either below or above, followed by the roof membrane. This membrane could be fully adhered, mechanically attached, or ballasted to hold it in place. In a PMR assembly (specifically Hydrotech PMR assembly), the roof membrane (MM6125) is fully bonded to the structural deck, followed by XPS insulation then ballast. Basically, the placement of the roof membrane and insulation layer in a PMR assembly is reversed or inverted.

In many cases slope in the roof deck structure may not be practical because of its size, shape, materials available, and cost, considering that it is typically more expensive to provide a sloped roof structure than a perfectly flat one. Therefore, the industry turns to various methods of adding slope to structurally flat roof decks. The resulting effort to provide slope is often in conflict with practical considerations and in the end, results in the owner getting a roof with serious built-in problems.

Two of the more common methods used to provide slope on flat concrete structural decks are by pouring on top of the deck a concrete sloped topping slab, adding a layer of screed, or by placing tapered insulation boards, specifically fabricated to fit the roofs configuration. The use of this secondary substrate to create slope can lead to numerous problems:

- The secondary substrate can trap moisture between the structural deck and the roof membrane during construction. This moisture present within the assembly can lead to membrane blistering and separation from the substrate (if adhered) and perhaps long-term deterioration.

- If the roof membrane were to leak for any reason, the leakage would not be readily traceable because water would be free to move laterally throughout the void (between the membrane and the structural deck), before finding its way to a crack or opening in the deck where it could enter the building. To trace and repair such a leak would be a nightmare and could result in the removal of much of the build-up covering the membrane in pursuit of the leak’s location.

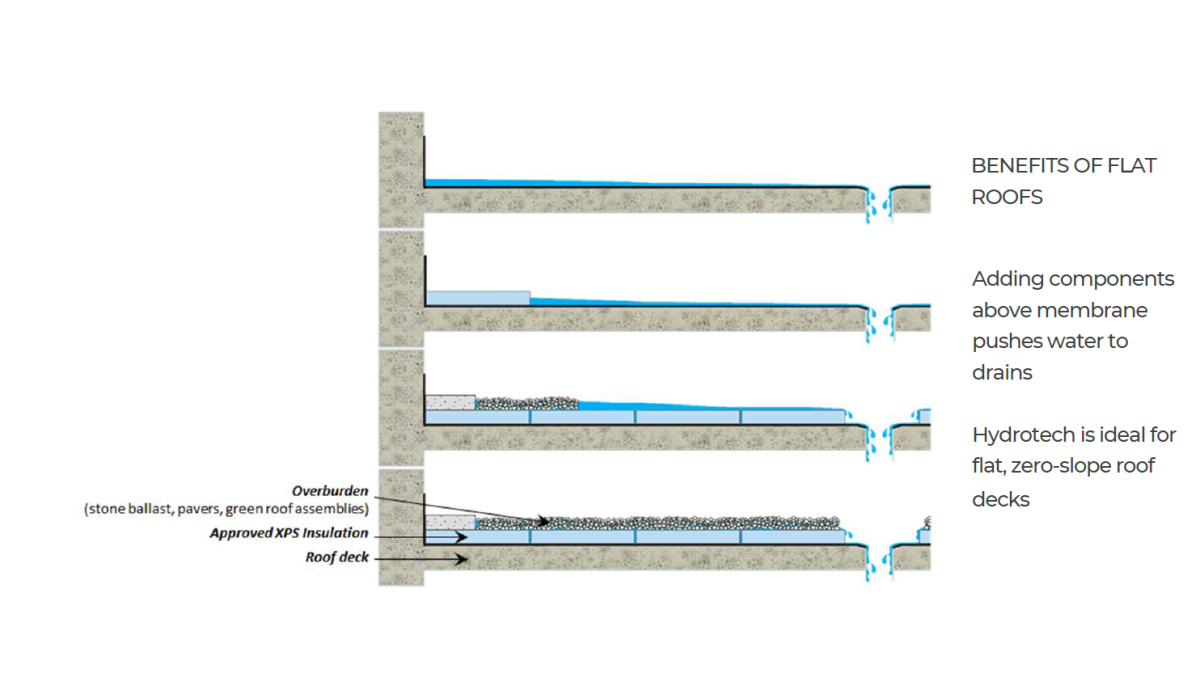

The above stated built-in problems are much more serious than lack of slope to drains in the function of a PMR assembly. With a PMR assembly on a zero fall/flat structural deck, upwards of 60% of the water flows over the XPS insulation layer to the drains, thereby creating a raised drainage level plane or “plateau drainage”, elevated well above the drains at the membrane level, thereby accomplishing all the functions of positive slope. The balance of the water in the joints between the boards flows freely to a drain, and any that finds its way beneath the boards is displaced by the boards and the ballast weight above.

Typical PMR zero-pitch roofs drain quite well because of the PMR design itself. A simple analogy can be used to illustrate this. Pour water on a flat surface and watch what happens. It moves to the easiest escape route. In the case of a table, the water will flow or be pushed towards the edge. On a roof the water pushes toward the drains. Taking the analogy further, place a solid weight on the liquid that is left on the table. The remaining water is displaced to the edge of the table, or in the case of a roof, the drains. Essentially, that is how PMR are designed. In service, the ballasted in place insulation in most cases does not allow water to build up in the first place. The space where water may accumulate is taken up by the insulation. As a result, the water that does not flow off the surface of the insulation is immediately displaced to the provided outlets. Furthermore, unlike conventional roofs which once wet, stay wet and deteriorate, PMR applications can dry out as they are designed as open systems (see assembly drawing in gallery above or online here).

For many years, architects have been choosing Hydrotech, hot applied rubberised asphalt membrane systems because they have clearly demonstrated long term performance, many times the life expectancy of conventionally built roofs. From a warranty standpoint, conventionally built roofing systems mimic code requirements through their warranties — they are void if the roof ponds.

Hydrotech has a long history of warranted applications where the area is intended to pond constantly and/or remain submerged indefinitely. Hydrotech globally offers, and has for over 50 years, full warranties for the weather tightness and material integrity of the MM6125 membrane regardless of whether the slope is provided in the construction.

Rubberised asphalt was conceived initially as a waterproofing membrane to be subjected to long term submersion. Fully protected, as it typically is in a PMR, water may sit in direct contact with the membrane indefinitely with no adverse effect on the material’s integrity.

The advantages of Hydrotech MM6125 PMR Assembly installed on a flat structural deck are:

- MM6125 is a seamless membrane, fully bonded to the structural deck, thereby (if damaged) eliminating the ability of water to migrate between the deck and the membrane. Any damage can be quickly traced and corrected, with minimal disturbance to the overburden.

- MM6125 was developed as a waterproofing membrane and has been used in reflecting ponds, pools, fountains, planters, etc., as well as in “flat” PMR assemblies for over 40 years! MM6125 is not affected by standing water.

- MM6125 is buried beneath several build-up and insulation layers, protecting it from the elements.

"Positive slope to drain” works best if it can be accomplished in the original structure and not by the installation of a secondary substrate to provide the desired slope.

“Raised plateau drainage” is an old concept that provides the benefits of slope, simplified construction, is cost effective and has a long successful track record.

Find out more about zero slope design by reading Allco's Auckland Library Green Roof case study.

To learn more about Allco’s products or get assistance with a project, specification or compliance please get in touch with the Allco team on 09 448 1185 or email [email protected]

Case Studies

Case Studies

Popular Products from Allco Waterproofing Solutions

Popular Products from Allco Waterproofing Solutions

Posts by Allco Technical

Posts by Allco Technical

Most Popular

Most Popular