Every design decision has cost impact, so how do you know what it is?

Too often we cost projects where the design far exceeds the client's budget. This is okay if we have become involved early at the concept stage as this is part of the process of figuring out what can be achieved. It is not good when we are pricing consent drawings and the price is way over the budget as by the time the project has got to this point, a lot of time, energy, and money has been invested.

One of the first projects we were involved with after starting YourQS was a renovation. The builder said, “the client loves the design, but I’m worried about their $400k budget.” The estimate came out at $1.3m so no wonder they loved it if they thought that they were getting it for $400k.

So why is this so hard? It stems from a fundamental misconception: while residential construction appears straightforward, two key factors create complexity:

- The sheer number of decisions, contracts, and transactions required for each project

- The relatively small scale and compressed timeframes of individual builds

The time it takes from when a design decision is made until the cost impact is known adds to the problem, making it more challenging for the designer to create a cost-feasible design. These factors, combined with the significant cost increases of the recent past, heighten project uncertainty and increase the chances of the client having a bad building experience. These bad experiences make homeowners reluctant to take on new building projects.

For renovation, extension, and bespoke new build sectors (bespoke building), establishing certainty is essential as each project is unique. This requires builders and designers to accurately assess scope and costs before completing designs.

What is cost certainty?

Cost certainty means accurately predicting a project's total cost before commencement. This crucial aspect of building management helps control overruns from quantity changes or resource shortages that inflate labour, materials, and hire costs.

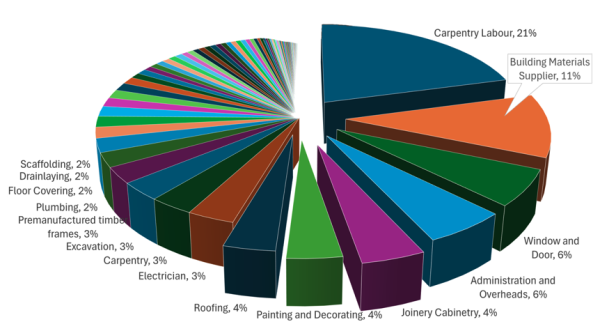

The challenge intensifies in bespoke building, where projects involve numerous suppliers and subcontractors. A typical house encompasses 75 separate cost centres, with 68 representing less than 5% each of the total build cost.

While many hope a single estimate from incomplete designs will predict all future costs, achieving true cost certainty demands ongoing planning, estimating, cost checking, quoting, and effective risk management.

Traditional estimating methods and timing

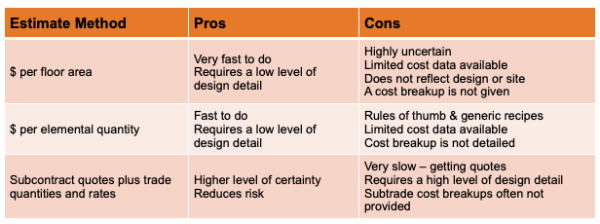

Three traditional methods exist for estimating building costs:

- $ per floor area: Calculating internal or gross floor area from plans and applying a rate based on historical data or market information. Areas are typically expressed in square metres.

- $ per elemental measure: Computing effective measures (areas, metres, volume, etc.) for each building element (substructure, upper floors, roof, exterior walls) and applying specific rates

- Trade quotes and estimates: Comprising:

- Subcontractor and supplier quotes

- Trade quantities and rates

- Preliminaries, indirect costs, margin and GST

The trade quotes method offers the highest certainty but requires fully resolved, construction-ready designs approved by the building certifier. This estimating method demands significant effort and typically takes a month or more to prepare, as it depends on subcontractor and supplier responses to lock in costs.

A new approach

In today's construction landscape, where cost assurance is paramount, technology enables a new approach: comprehensive estimates from preliminary sketches, supported by 3D visualisation to clearly delineate inclusions and exclusions. This bridges the gap between early planning needs and detailed cost certainty.

To stay competitive and maintain client confidence, the industry must embrace systematic approaches to cost estimation. Consider how your current methods align with project complexity and client expectations. Are you providing the level of certainty your clients need? The investment in proper cost planning today can prevent significant variations and challenges tomorrow.

Thanks to David Mitchell, Director, YourQS Aust Pty. FAIQS, MRICS for his thoughts and contribution to this article.

Most Popular

Most Popular Popular Products

Popular Products