In our most recent article, we talked about the importance of acknowledging a person’s individual characteristics, for example, their skills and motivation, when wanting to achieve a preferred outcome. We stressed the importance of integrating the people factor in the passive fire sector for tasks to be successfully and compliantly completed.

Today we want to look further into the second of the three human factors, the cultural/organisational element, and elaborate how this aspect is crucial for the successful completion of work instructions.

Organisational/Cultural Factors include (but are not limited to)

- Organisational structure

- Demonstration of values and objectives, goals and priorities

- Level and nature of supervision/leadership

- Clarity of roles or responsibilities

- Teamwork, coordination, staffing levels

- Communication lines/quality

- Quality Management Implementation

- Consequences of failure to comply with procedures and processes

- Effectiveness of organisational learning/training

- Safety culture

Let us show you how a focus on having clear roles and responsibilities, suitable procedures, appropriate training and the right level of supervision, etc. will go a long way to complete a compliant and successful project.

Root cause analysis

On multiple occasions we have encountered that coating application issues identified on floor level are habitually interpreted as a skill or competency failure on part of the applicator. We are prone to attribute the root cause to the person that made the error.

This spontaneous interpretation of the situation however, is often nothing more than creating a pseudo-causality that doesn’t exist and ignores many wider issues. Unfortunately, we are inclined to stick with this initial reaction as it seems to be the easiest and most manageable solution to our problem.

When we take the time to sit back and rethink our initial reaction, we will see that we frequently omit to recognise the effects that have potentially trickled down from the top and have then created an error on the bottom.

From our experience we strongly believe that it is crucial to change our thinking and dig deeper to accommodate these effects.

Hierarchy of controls

“The majority of accidents and incidents are not caused by ‘careless workers’ but by failures in control, which are the responsibility of management.”

This quote by a UK health expert indicates why fixing the problem on the lowest level might lead to immediate, short-term success but is unlikely going to be sustainable. To illustrate this further we want to utilise a model from health and safety management: the hierarchy of control structure.

I imagine most of you are familiar with the structure so I will only briefly outline the concept’s main idea.

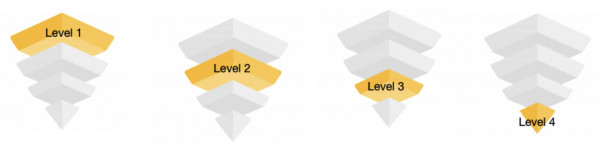

The hierarchy of control is a widely employed concept and provides a level approach. To successfully avoid issues it uses an order of priority for taking measures if something goes wrong.

- Level 1: Elimination — Redesigning the work task is the most effective control.

- Level 2: Minimisation — Replacing the process with a more suitable one.

- Level 3: Administrative Controls — Implementing procedures to support compliant behaviour of the worker.

- Level 4: Direct Control — The use of PPE etc. to directly protect the worker.

The concept explicitly calls for a top-down approach to reduce issues to the lowest level possible. This simply means that effectively implementing measures must start at the top. The more severe the potential consequences or number of people affected, the more important it is to focus on controls at the top of the hierarchy.

It is the innate responsibility of the leadership and management team to eliminate or at least minimise any problems from occurring in the first place and facilitate the proper context for people to work in.

Only after that we should work our way down the list. The bottom two levels rely heavily on fixing the worker by implementing work instructions and direct controls. They should be regarded as the last resort as they are the least effective controls and are only helpful in combination with higher-level control measures.

Managing worker behaviour should never be used to compensate for poorly designed workplaces.

Even though this approach illustrates in a simplistic manner that the responsibility lies with the management, it has clear limitations when it comes to achieving outstanding work performance. Therefore, we want to offer a different perspective.

Leading by example: From control to commitment

We need to acknowledge that a company’s success and sustainability depends heavily on the management of the company and the leadership providing the competent employee with the necessary direction, resources and support, to produce quality performance.

Choosing the right management approach is crucial: It needs to not only reflect modern workplace and employee requirements but also be suitable for the industry the company works in.

As a company working in the Passive Fire Industry, we are mainly engaged in complex work environments with multiple stakeholders, involved project management setups and changing requirements. Based on this we want to promote a strategy based on eliciting commitment. The commitment model is much better suited for situations that require intricate teamwork, problem solving, organisational learning, and self-monitoring than a traditional control model.

Although commitment can grow in a natural way, management can foster commitment directly and build it into their culture.

This requires supervisors to promote rather than direct/control the work force, to communicate rather than solely practice their technical expertise, and to support workers to develop the ability to manage themselves. In other words a high level of trust is necessary in the relationship between leaders and employees. In this way people are encouraged to take responsibility to self-supervise work teams that are collectively responsible for a set of related tasks.

We currently see the restrictions of this approach in real life as the management that is the central element to this strategy shift is not having the necessary competencies. They often have not received adequate training and/or support for their new tasks or are not having their own needs recognised. This leads to pointing fingers rather than the management taking responsibility for their actions.

There is a fair share of work ahead of us to facilitate this change. As a first step it would be essential to create adequate training for management to allow the necessary shift to happen and for companies to live up to their full potential. This way a commitment strategy is able to open the door to achievement and allow for a superior level of performance and market success.

Conclusion

We hope we were able to show how integrating the cultural/organisational setup into implementing new industry requirements helps to facilitate a successful completion.

Acknowledging the importance of the quality of management including its competencies will help to create a sustainable and successful business.

Direct controls of the employee have severe limitations and understanding that there are a range of measures which are more effective is crucial. Sharing knowledge and evidence that allows employees to understand and therefore commit to a certain task far outweighs creating guidelines that people need to follow religiously with compliance being the first objective.

Striving for the overall goal of commitment has a huge potential to produce reliable if not outstanding performance long-term and requires a shift in management philosophy and the strong commitment of employees.

In our next and last article in this series we want to look into how designing the actual work task and direct work environment can further aid to facilitate compliant behaviour and successful completion.

Most Popular

Most Popular Popular Products

Popular Products