In last month’s blog post, we thoroughly investigated the three challenges the industry is facing in regard to upgrading fire-separating elements: Comprehension, Complexity and Compliance.

In the third and final part of our series we want to demonstrate how a tested and endorsed intumescent coating system embedded in an integrated approach is able to deliver a compliant, cost-effective, minimal waste solution.

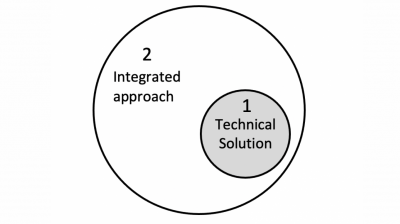

Offering more than a technical solution

It goes without saying that with the multitude of challenges arising around upgrading fire-separating elements an all-encompassing solution can only be achieved by approaching the situation with fresh eyes. Over the past three years, we have been meticulously looking at these challenges, which made us realise that a resolution was never going to entail a technical solution alone.

While there is definitely a need for passive fire protection to move into the future, there most certainly is also the requirement for a more integrated way of thinking when designing, specifying and installing fire-separating elements.

In the following paragraphs, we want to discuss the technical as well as the non-technical facet of a reliable solution to the passive fire problem we are facing.

The technical side of the solution: intumescent coatings

While adding or replacing plasterboard is still a heavily employed solution in the industry, it does not match the requirements of our time — namely being compliant as well as being timely, cost effective and environmentally friendly.

However, the current generation of intumescent coatings tick all the boxes and have an established performance, when correctly specified, installed and quality controlled. Hence, instead of replacing a system, which is otherwise fit for purpose, why not simply increase the FRR of an existing fire-separating element with each coat of intumescent coating applied?

This presents a huge advantage, as it allows remediation work to be done in a fraction of the time and significantly reduces building waste and costs. It requires fewer trades to be involved on site which also reduces potential delays and issues caused by handovers.

Only intumescent coatings make it possible to carry out remediation work in very restricted spaces like riser shafts, with their multitude of service penetrations and minimal impact requirements, as none of the utilities need to be disconnected. Additionally, emergency corridors and stairwells, which are means of escape or safe refuge, can be upgraded in a live building.

With properties like low-VOC and low-odour, as well as a very limited amount of noise during application, the impact on occupants is minimal and the building can continue to be used while remediation work is carried out or very shortly after.

Testing for compliance

None of the before however is of any relevance if the intumescent coating is not a compliant, endorsed system, tested in accordance with the requirements of the Australasian market.

One of the cornerstones to producing a tested and endorsed solution is to test on specimens made from locally sourced materials, manufactured in Australasia, constructed in accordance with local construction standards and carefully following the local linings manufacturer’s instructions. The other is ensuring a test regime fulfils the requirements of AS1530.4:2014, the current version of the testing standard stated in the NZBC and NCC.

It is often overlooked however that a comprehensive understanding of compliance is only half of the picture, a detailed decoding of the existing system is of equal importance.

We believe that diligent decoding of existing systems is only possible by partnering with experts from adjacent disciplines and applying inspection best practices.

Integrated approach: understanding inputs and outputs is key to a sound solution

Most likely, upgrading the fire-separating element will be one of many aspects of a comprehensive remediation project and consequently, it needs to be aligned within its bigger framework.

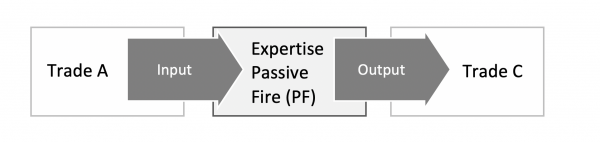

We have encountered first-hand how the independent work of different trades — within passive fire and outside, in general construction — often conflicts with each other and that even the best solution will not be able to remedy the challenges we are facing, if it is stand-alone. Only an integrated approach across disciplines will lead to success.

To paint a clearer picture, we want to utilise an approach used in Quality Management: Every process is guided by its inputs and outputs, or to put it in simple words, no process is ever independent.

Understanding how inputs will affect the performance of your product and how your outputs might affect the following trade is essential. High quality results can only be achieved when consideration is given to the interactions with other trades. We need to step up and look outside the box.

We strongly believe that as a supplier your job starts well before you even sell a bucket of paint and extends way beyond it — this means correctly decoding the existing system as well as realising how any follow up work will be affected by or affects your outputs.

That is why we believe that running research tests on common crossover challenges is important. Only thereby one can answer questions e.g. whether passive fire stopping needs to be done before or after upgrading or if overlays such as banister brackets, dado rails, plywood and commercial linoleum, that might be fixed or glued to an emergency corridor after applying a coating, have an impact on the performance of the passive fire system.

Outlook

Often, we are brought in when things need fixing, when fire-separating elements have NOT been dealt with according to specifications or manufacturer’s instructions. And even though our system and approach has proven to remedy the most complex scenarios, shouldn’t it be our goal to not even let it come to this point?

If Passive Fire Protection, with a focus on fire-separating elements, wants to become a respectable discipline within Fire Design, it needs to step up its game.

We have set our goal nothing lower than creating a best practice for the specification, application, and quality control of intumescent coating systems for non-ferrous substrates.

Aligned with other disciplines we suggest the following:

Passive Fire Solutions for non-ferrous substrates need to:

- Be tested and endorsed according to test standards required by the NZ Building Code

- Guided by a Code of Practice

- Embedded in a robust Quality Assurance system at all stages

- Allow for an interdisciplinary approach and include trainings

Conclusion

We truly believe that only a high-quality, tested and endorsed intumescent coating solution embedded in an integrated approach will be able to remedy the current passive fire problem and lead to long-term success.

We hope we were able to demonstrate what a sustainable, minimal waste, cost effective and minimally disruptive solution can look like and that intumescent coatings are the future of upgrading fire-separating elements.

Why settle for less if you can have it all?

Special thanks

None of our insights would have come about without opening our questions to more than just passive fire. We want to thank the numerous people, who have taken the time to listen to our questions and provide us with valuable feedback, for their support.

Most Popular

Most Popular Popular Products

Popular Products