There are a wide range of floor waste designs on the market, each with features to suit different applications and installation methods. When selecting floor wastes in projects that require passive fire rating some consideration should be taken to the system's compatibility and the Passive Fire Protection (PFP) product selected.

The penetration / core hole through the flooring structure should be kept as minimal as possible for fire rating. Easy clean wastes that use a bucket and funnel design are often supplied with shower trays. They provide an excellent solution for squat flooring cavities; however, they do require larger core hole sizes to be cut and have minimal testing for passive fire protection.

In accordance with AS 4072.1-2005 an install scenario that hasn’t been tested can only be used if it is:

a) approved by the regulatory authority;

b) permitted in accordance with AS 1530.4; or

c) formally assessed by a registered testing authority

As mentioned above, large core holes for easy clean wastes may not have the testing needed for the installation scenario, this would likely result in a fire engineer designing an alternative solution. Some local authorities such as Auckland Council have gone as far as stating that an alternative PFP solution should only be used if a tested solution is not readily available. Utilising tested solutions through considered product selection streamlines the process by not relying on additional input and consultation.

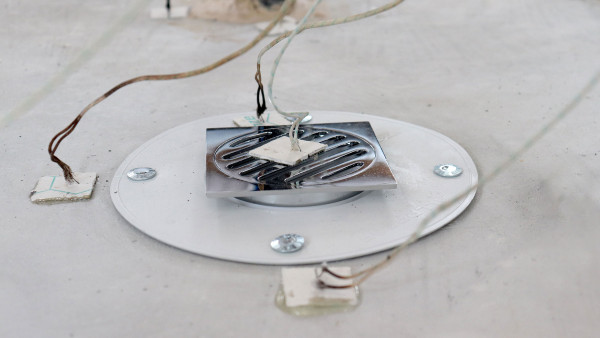

Selecting products such as Allproof’s Trayrite allows the tray waste system to be converted to a traditional floor waste gully, providing a fully tested passive fire solution for shower trays. An added benefit to a traditional floor waste gully is the reduced maintenance as they are considered self-cleaning, water pressure from modern systems washes away any debris.

When testing PFP products in accordance with AS 1530.4:2014 on floor wastes a temperature sensor is positioned directly in the centre of the open metallic or plastic grate, or the area with the highest exposure to heat, as the water trap below combusts/melts.

Allproof’s advanced NZ made intumescent is able to activate and close the opening before exceeding the temperature allowance on the thermocouple, giving a full FRR result for insulation and integrity.

Allproof have floor waste results for the below flooring systems with a range of PFP products:

- Concrete slab

- Composite steel tray floors

- Rib and timber Infill

- CLT

- Plasterboard ceiling

Designers have taken advantage of Allproof’s fully tested plumbing and PFP systems with projects such as Seascape in Auckland, who have selected NZ made custom tile over stainless trays with drop in fire collars for composite steel tray floors. Other examples include Kāinga Ora developments where an Allproof exposed stainless, or an acrylic shower tray, has been used with Trayrite on a wide range of floor systems with an Allproof PFP solution.

Selecting PFP manufacturers that specialise in the systems passing through fire cell penetrations means designers can benefit from fully compatible and innovatively designed solutions. These integrated systems improve the selection, design and installation aspects of both the plumbing and passive fire protection.

Allproof’s testing and assessments are conducted by independent accredited testing laboratories. Further to this, Allproof’s PFP range and literature has been BRANZ Appraised, ensuring integrity and providing utmost assurance in selection, performance and installation.

Most Popular

Most Popular Popular Products

Popular Products