What if:

- a lightweight decking subframe could be supplied as components, kitset or pre-manufactured to size and delivered to site just like aluminum joinery?

- a deck frame was light enough for 2-4 people to lift off a truck and position into place?

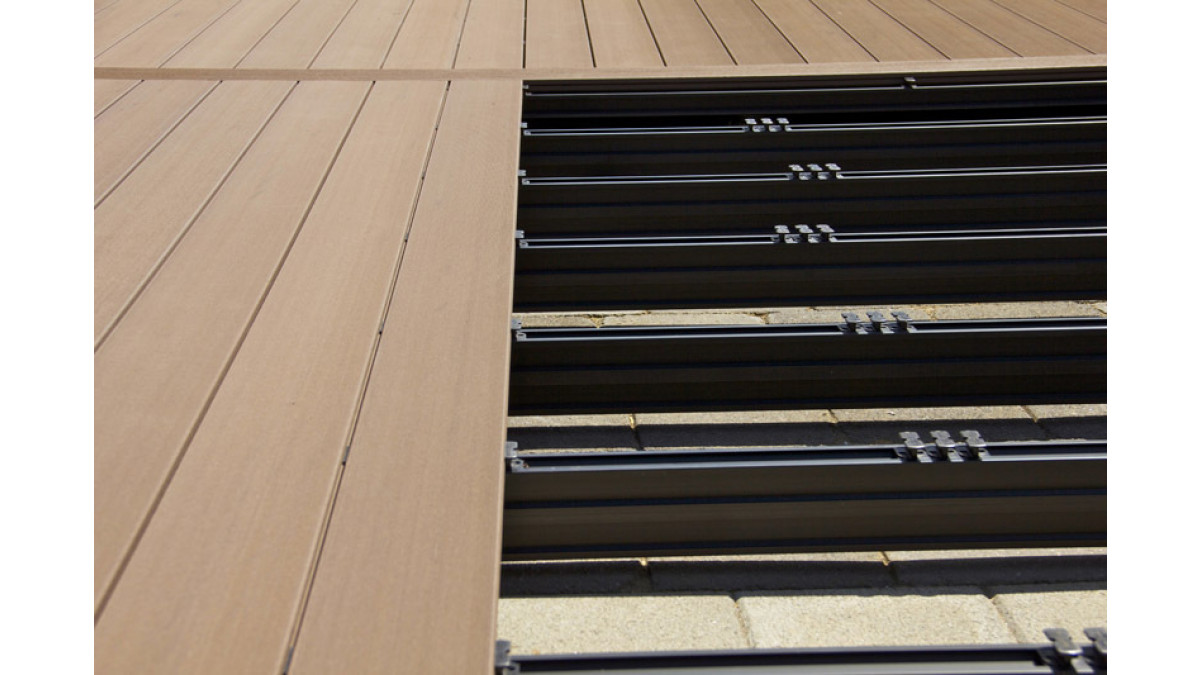

- decking boards could to be installed using no screws or nails?

- a 25 square metre deck installation including sub-frame and decking board could be completed within five hours?

Break decades of traditional primitive deck construction, working with wet, heavy, chemically soaked timber joists, and time-intensive, weather-dependent installations. Now you have an alternative to using tiles on fiddly deck jacks, or unstable, unrestrained timber joists, ripped in width to match a membrane deck's fall.

The concept is simple. Replace the cost of installation time and poor quality materials with quality, moisture-resistant materials and speedy project completion, plus the assurance the deck will stay straight and level.

Qwickbuild offers benefits such as low height, long span, high load substructure framework. It is perfect for use over waterproof membrane decks whilst allowing access and ventilation, maintaining the membrane's integrity. It is unaffected by moisture, offering vastly superior durability and dimensional stability compared to any deck over membrane system or traditional timber pile, bearer, joist construction methods.

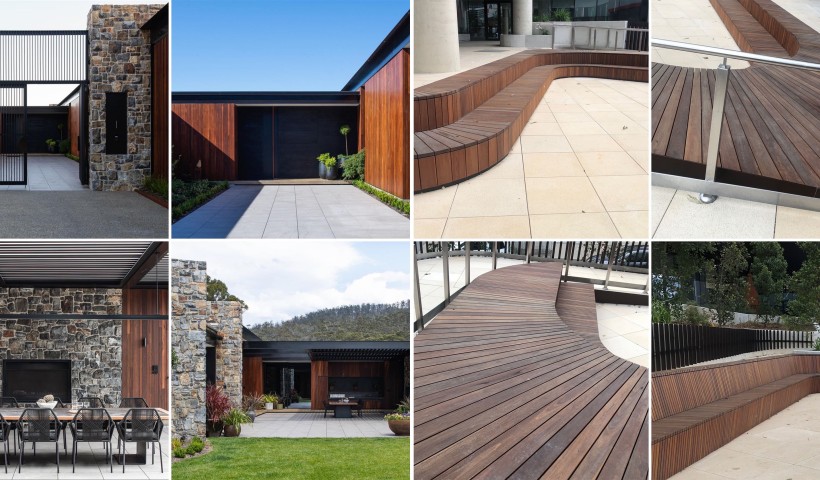

Qwickbuild has been designed and developed as a complete system integrating with any of Outdure's Eco-Decking composite decking board and accessories range, and also traditional timber decking boards. It is designed and developed locally and sold globally (international patents apply).

Case Studies

Case Studies

Popular Products from Outdure

Popular Products from Outdure

Most Popular

Most Popular

Popular Blog Posts

Popular Blog Posts